|

|

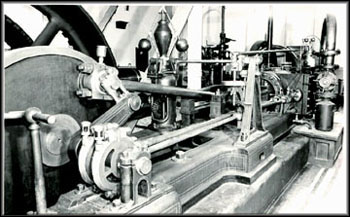

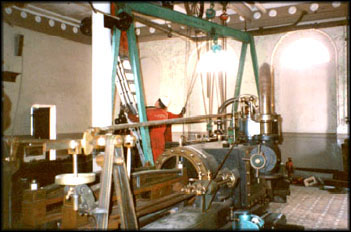

INTRODUCTION The following two articles and correction in a letter to the editor appeared in ISSES bulletins volume 18, and relate to the removal of a pair of Thornewill and Wareham steam engines from Wilderspool Brewery in Warrington, England by ISSES member Tommy Nuttall. NEWHOME FOR GREENALL ENGINES by John Cooper The Road to Removal The power house at Greenall Whitley's Wilderspool Brewery in Warrington was one of the finest surviving examples of the type in this Country. It contained three good sized steam engines located in a magnificent glazed tile and marbled column room. Up to until the point when the brewery closed it was all in good condition and in its original state. Readers of the bulletin will have noted that in SB 12.4 we reported the closure of the brewery as the owners dropped out of the brewing business, got another brewery to supply their ales and concentrated on the running of their hostelries etc. In IB 17.4 we reported that the building was receiving major attention, including demolition of the more modern sections of the brewery and conservation work on the original buildings. Occasional visits past the brewery showed work on the buildings had started with the removal of the 'modern appendages', shortening of the chimney and general repair work on the old tower brewery. A conversation with a member of management revealed that the engines were still intact, although unkept, but their future was uncertain. Unfortunately, the plans for refurbishing the site as office accommodation did not include retaining the engines in situ, leading to the inevitable news that the engines had to be removed. As ever, when this news came, the removal of the engines had to be done within two weeks. Fortunately all the engines have now been safely removed from the buildings and are surviving currently. The Company Thomas Greenall originally started in the brewing business in 1762 when he set up his own premises at Hardshaw near St Helens in Lancashire. He built up the business and supplied ales to Merseyside, North Wales and the immediate towns. In 1787, with two partners, he purchased Wilderspool brewery then owned by Saracen's, together with another brewery in Liverpool. The latter establishment was closed down in 1814 during a difficult period for brewers with a reduction in demand for ale during the period of the war with France. Upon Thomas's death in 1807, the business was left to his three sons. The Partnership became Lyon and Greenall and saw a period of expansion. The Company was involved in many takeovers, particularly since the First World War, and in recent times this saw the acquisition of Shipstone's of Nottingham (in 1978) where Greenalls continued to brew, and Davenport's of Birmingham (in 1986). All this activity saw Greenall Whitley became one of the biggest brewers outside of 'the big six'. In 1990 the company announced their intention to close down Wilderspool brewery as they moved out of brewing and into the leisure side of their business. Steam power The splendid power house contained three largish steam engines. These comprised a pair of Thornewill & Warham of Burton-on-Trent single cylinder rotative engines, that drove the brewery machinery by belts off their flywheels, and a steam powered refrigeration unit. This latter was an unusual sight in a British brewery. The oldest engines were the Thornewill & Warham's that were installed in the brewery in 1884, being built as the manufacturer's numbers 524 & 525. They are an opposite handed pair with the two flywheels standing side by side. The bed plates, frames etc are painted in dark green with yellow and red lining out. The wood lagged cylinders have a c18" bore and a stroke of 3'. The cylinders are fitted with a large valve chest containing slide valves with a variable expansion cutoff. These are driven by two eccentrics situated on a layshaft more or less in line with the crankshaft and turned via a drag link off the large disc crank. The expansion cut off is manually adjusted by a large handwheel positioned by the slotted expansion link. Cutoff is varied by adjusting the relative position of the valve rod and eccentric rod in this slotted link. There is a brass pointer that indicates the cutoff point on a brass plate. There is a tail rod for each of the two valve rods. The governor is driven by a bevel gear contained within the governor base, with power provided by a short horizontal layshaft that is turned from the crankshaft by a belt. There is a high level link from the governor to adjust the throttle valve. The flywheel is a two piece, six spoke wheel of 8'6" diameter with a rim width of 25" from which a wide belt drove up to line-shafting situated over the two engines. The engines are hand barred from teeth set in the inner face of the flywheel rim. There is a disc crank of 46" diameter by 6" width and four bar crosshead guides. The third engine that was located in the same room behind the Thornewill & Warhams was a horizontal single cylinder rotative ammonia compressor for refrigeration. This has a plaque on the bed of the pump side and a brass plaque on the wall pronouncing it as "Linde System; The Linde British Refrigeration Co. Ltd., London". However, it is now known that the engine was actually built by Davey, Paxman & Co. Ltd. of Colchester, who built many engines for Linde. It was installed in 1902 and has the same colour scheme as the other engines, including a painted cylinder cover. |

|

The steam cylinder is 19" bore by 2' stroke and is a fitted with a slide valve with expansion gear. According to the Paxman records, accessed by ISSES member Alex Walford, the engine was rated at 55 ihp at 65 rpm. The compressor is driven from the crosshead in a 'cross' formation and according to the Paxman records is a No. 5A compressor. By on-site measurement, the cylinder is c12" diameter x 3' stroke. The steam side has a trunk crosshead guide with a single slipper on the compressor side. The compressor is mounted on a single cast iron bed, but the steam side has a separate mounting for the cylinder bolted down to a concrete bed and a mounting under the crank bearing bolted to a separate concrete upstand. In the middle of the two cranks is the two piece six spoke flywheel of 8' 6" diameter x 12" wide. Barring was achieved through teeth cast on the inner rim of the flywheel like the other two engines. Both sides have single slab cranks. The steam side has a strap big end and box little end, with a marine big end and forked little end on the compressor side. The Governor is a Hartnell type, to Paxman's own design, that adjusts the Hartnell expansion linkage. The refrigeration unit last worked in the late 1930s but the Thornewill and Warham engines were used until 1962. There was a forth steam engine on site, although this was located outside of the main power house and was in a slightly tatty condition. This was a small inverted vertical single cylinder Tangyes which drove a well pump. It has a steam cylinder 4½" bore by 4" stroke and was fitted with a piston valve. The flywheel was 2'6" diameter and had an inertia type flywheel governor. On the opposite end of the crankshaft there was a belt pulley of 28" diameter. It is good to report that all the engines have been saved. The two Thornewill and Warham engines have remained as a pair and have been taken by ISSES member Tommy Nuttall to add to his growing and significant collection at Markham Grange Nursery. The engines are currently in store under cover in the building containing Tommy's generating engines and will be incorporated into the new display building being planned. The refrigeration engine is reputed to be in the hands of the demolition contractor and will hopefully find a safe home. The small Tangyes has found a home with Fred Dibnah. LETTER TO THE EDITOR: WILDERSPOOL BREWERY, WARRINGTON: A CORRECTION BY COLIN BOWDEN Dear Editor, John Cooper provides a useful description of the engines at Greenall Whitley's Wilderspool Brewery on the occasion of the loss of yet another important site - as a result of what can only be described as vandalism on the part of the company concerned. However, the compressor stroke given is incorrect (my record card has 21" rather than the 36" given) and the correct stroke has now been confirmed by further details from the Davey, Paxman records, kindly supplied by Alex Walford: Order No. 6431. Entered 30 September 1901. In practice the steam pressure used was 60 psi and at some stage the running speed was raised to 75 rpm. Another question which is perhaps worth raising concerns the governor, described in the specification as Davey, Paxman's "new adjustable high speed type", but which is stated in the article to be a "Hartnell type". Possibly these two descriptions are not incompatible but, superficially at least, it certainly doesn't look much like the normal Hartnell governor! Could a governor expert settle this? Interestingly, the records also show that parts for the compressor were still being supplied by Davey, Paxman in the 1940s, thus disproving the previously accepted "late 1930s" stopping date; a new compressor piston rod was supplied in July 1941 and a neck bush for the compressor in November 1947. IT'S

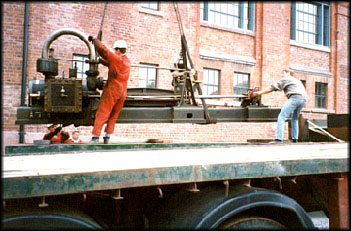

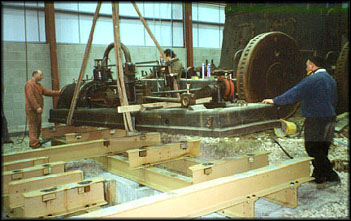

AN ILL WIND On 24th April, I received a letter from the secretary of ISSES, Mr. John Cooper informing me of some interesting engines that had to be removed from Greenall Whitley's Wilderspool Brewery in Warrington as a matter of extreme urgency. Mr Cooper having tried to contact me by phone without success, hence the letter; the 'urgent' matter was now some days old. Next morning began with some frantic phone calls to the Brewery. The works' engineer not being available I was put through to Ann, who was very helpful, said "yes, she knew of the engines and yes they had to be removed quickly" and promised to ring me back. After about two hours, excitement was just about to go ballistic when the promised call was returned, "Mr. Nuttall", "yes", "about the steam engines", "oh yes", trying to control the voice tremor. "I'm sorry! but they have been sold!" Long pause from me; probably in a slightly different tone of voice, "do you know who to?" reply "sorry I'm afraid I don't". End of story, or so it seemed. After I'd (as our younger members of staff term it ) stressed down, which was not until the next day, I rang Mr Cooper to inform him of the bad news and asked him to keep his ear to the ground for any news of the engines' whereabouts. A couple of weeks later I was talking to my friend George Drake, curator of the Calderdale Museum in Halifax, telling him the sad story, also with the same request, seeking the engines' whereabouts. Another week passed, then George rang back with some information. Apparently the small Tangye had gone to Uncle Fred (Dibnah). The other to the managing director of Manchester Demolitions and the two Thornewill and Warhams to Alan McEwan (him of Lanky Boiler front in his dining room, see Old Glory issue no: 76.) Well at least they were safe. Another week passed when one of our girls came to see me with a message from George Drake asking me to return his call as he had some good news, re: the two Thornewill engines. Returning George's call that evening he told me to ring Alan as soon as possible because there had been a change of plan. So, next call to Alan. Now Alan is a very busy man trying to earn a crust, like the rest of us, and he was so committed right now he couldn't possibly spare the time to do the Warrington job. He asked if I would be interested in taking over, ( would I!) and quickly, as the engines had to come out next week. Next day ( Monday ) after a few wrong and misdirected phone calls I managed to get to the right people. Explaining that Alan could no longer do the job and we would be pleased to take over, could we come the next day to assess the situation, method, tools required, etc. Much to my surprise the reply was, "yes, please come and have a look, but on no account touch anything or interfere as all the dismantling and removal was in the hands of contractors". So arriving on Tuesday morning Steve, our works engineer and I were amazed to find both engines partly dismantled and ready for removal. I must say the sight that greeted us was unforgettable. Two Thornewill and Warham engines, Nos 524 & 525 (1884) in perfect and original condition. After a quick chat to the contractors Sparrows, the crane people, and a wager on the weight of the bedplate, cylinder, connecting rod and valve gear, which was to be lifted in one lump; we stood back and watched someone else do the work. That in itself made a nice change. The lost wager cost me a pint, I estimated 10 tons, Sparrows' foreman 5 tons, actual weight 6½ tons, mind you, they do have a great deal of experience. So everything was under control. The tricky bit was getting them down to ground level. The engine room being on the second floor and approximately 30' above ground. This entailed a very substantial scaffolding job, capable of carrying 13 tons, this again all being erected by Sparrows. The work was far enough advanced to start organising some transport. So a quick phone call to our local haulier and two 40' artics were to be laid on, one for Wednesday and one for Thursday. After a brief hiccup whilst the safety officer and some 13 ton weights could be found, the scaffold was duly tested and engines drawn onto it and lowered safely onto the waiting transport. By Friday everything was back at Markham Grange and we hadn't even had our hands dirty. I must finish by offering my sincere thanks to all involved in the project: Jane Williamson, Nick Cowie, Alan McEwan, John Cooper, George Drake, Sparrows, but most of all to Greenall and Whitley, who apart from wanting the engines preserving, organized and paid for everything. I'm sure myself and all steam nuts will be eternally grateful. STOP PRESS More good news! planning permission just granted for new building ( to put them all in ). SO IT'S FULL STEAM AHEAD ! |

|